Products

From cultures to packaging, including equipment, here is our range of products.

Casein label

Casein thin disc that is inserted in the mould before moulding, pressing or acidification.

This protein-made label will fuse with the cheese and mark it thereafter.

Color, size, shape and prints are possible options when choosing this product.

It is also possible to write on the label with a food-grade pencil.

Casin labels can be printed with a logo, a sequential code (each label has a different code), a DOP, AOC or certification, a datamatrix code, an RFID chip or any useful information.

Since the label remains on the cheese, it is a great traceability tool to use.

Polyflex white

It's the perfect wrapping solution both for commercial or domestic use. Polyflex allows air exchange and longer shelf life.

Thanks to its interior coating, you can now keep aromas where they are meant to be.

Each package contains 500 sheets.

CHY-MAX® M coagulant 5 gal

CHY-MAX® M is a pure chymosin produced by submerged fermentation on a vegetable substrate with Aspergillus nigervar.

awamori kept under contained conditions and not present in the final product.

The product contains a milk-clotting enzyme which is highly specific for kappa-casein, resulting in very good curd formation.

The general activity also has a significant influence on the flavor and texture development of cheeses.

The active milk-coagulating enzyme is chymosin (EC 3.4.23.4).

MA 4002 Freeze-dried 25 DCU

Freeze-dried concentrated lactic starter for the direct vat inoculation of milk and milk bases.

MM 101 Freeze-dried 125 DCU

Freeze-dried concentrated lactic starter for the direct vat inoculation of milk and milk bases.

MA 4001 Freeze-dried 25 DCU

Freeze-dried concentrated lactic starter for the direct vat inoculation of milk and milk bases.

MA 11 Freeze-dried 250 DCU

Freese-dried concentrated lactic starter for the direct vat inoculation of milk and milk bases.

KL71 Freeze-dried 10 D

Yeast for des-acidification in cheese making and aroma developing.

MM 100 Freeze-dried 50 DCU

Freese-dried concentrated lactic starter for the direct vat inoculation of milk and milk bases.

MM 100 Freeze-dried 125 DCU

Freeze-dried concentrated lactic starter for the direct vat inoculation of milk and milk bases.

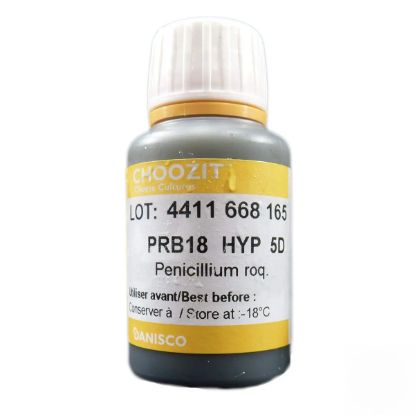

PRB 18 Liquid - Hyptonic 5 D

Blue mould in liquid suspension form for cheese production.

Direct inoculation of cheese milk.

We do not accept any liability in case of undue application.

Stainless steel aging rack 630 x 510 mm, 25 wires, H120/100 mm (Reinforced)

For a homogeneous rind development

The racks are assembled in stacks, leaving sufficient space for uniform ventilation of each cheese.

Racks constructed from stainless steel wire are a flexible solution that optimizes space in the factory, from storage to use.

Our wire stainless steel aging racks are used for ripening, brining and drying cheeses allowing an optimal ventilation and support of the products.

The choice of rack size should be done according to the cheese size and type.

They stack legs on legs to create shelves where the cheeses can be placed.

This modular solution will optimize the space in the room allowing an even result and an easy manipulation.

It suits well for fresh, soft and semi-soft cheeses, blue cheeses and other varieties that need to ripen or dry.

Made in #304 SS.

Assembly of the wires on the frame by food-grade spot welding.