Products

From cultures to packaging, including equipment, here is our range of products.

Ripening mat straw type 69 cm x 25 m

Mats for covering racks

Covering racks with mats helps minimize the marking of delicate cheeses.

Ripening mat straw type 69cm x 1m

Mats for covering racks

Covering racks with mats helps minimize the marking of delicate cheeses.

Ripening mat diagonal 50 cm x 1 m

Mats for covering racks

Covering racks with mats helps minimize the marking of delicate cheeses.

Ripening mat diagonal 50 cm x 25 m

Mats for covering racks

Covering racks with mats helps minimize the marking of delicate cheeses.

Stainless Steel Aging Racks 850 x 510 mm, 25 wires, H130/100 mm

For a homogeneous rind development

The racks are assembled in stacks, leaving sufficient space for uniform ventilation of each cheese.

Racks constructed from stainless steel wire are a flexible solution that optimizes space in the factory, from storage to use.

Our wire stainless steel aging racks are used for ripening, brining and drying cheeses allowing an optimal ventilation and support of the products.

The choice of rack size should be done according to the cheese size and type.

They stack legs on legs to create shelves where the cheeses can be placed.

This modular solution will optimize the space in the room allowing an even result and an easy manipulation.

It suits well for fresh, soft and semi-soft cheeses, blue cheeses and other varieties that need to ripen or dry.

Made in #304 SS.

Assembly of the wires on the frame by food-grade spot welding.

Stainless Steel Aging Racks 780 x 560 mm, 44 wires, H150/120 mm

For a homogeneous rind development

The racks are assembled in stacks, leaving sufficient space for uniform ventilation of each cheese.

Racks constructed from stainless steel wire are a flexible solution that optimizes space in the factory, from storage to use.

Our wire stainless steel aging racks are used for ripening, brining and drying cheeses allowing an optimal ventilation and support of the products.

The choice of rack size should be done according to the cheese size and type.

They stack legs on legs to create shelves where the cheeses can be placed.

This modular solution will optimize the space in the room allowing an even result and an easy manipulation.

It suits well for fresh, soft and semi-soft cheeses, blue cheeses and other varieties that need to ripen or dry.

Made in #304 SS.

Assembly of the wires on the frame by food-grade spot welding.

Ripening mat square mesh 1 m x 1 m

Mats for covering racks

Covering racks with mats helps minimize the marking of delicate cheeses.

Ripening mat large mesh 1 m x 20 m

Mats for covering racks

Covering racks with mats helps minimize the marking of delicate cheeses.

Ripening rack 630 x 510 mm, 31 wires, H85/55 mm

For a homogeneous rind development

The racks are assembled in stacks, leaving sufficient space for uniform ventilation of each cheese.

Racks constructed from stainless steel wire are a flexible solution that optimizes space in the factory, from storage to use.

Our wire stainless steel aging racks are used for ripening, brining and drying cheeses allowing an optimal ventilation and support of the products.

The choice of rack size should be done according to the cheese size and type.

They stack legs on legs to create shelves where the cheeses can be placed.

This modular solution will optimize the space in the room allowing an even result and an easy manipulation.

It suits well for fresh, soft and semi-soft cheeses, blue cheeses and other varieties that need to ripen or dry.

Made in #304 SS.

Assembly of the wires on the frame by food-grade spot welding.

Ripening mat straw type 69 cm x 25 m

Mats for covering racks

Covering racks with mats helps minimize the marking of delicate cheeses.

EASY-SET® A955

The culture is primarily applied in the production of Cheddar, Colby and Monterey Jack cheese.

EASY-SET® A965

The culture is primarily applied in the production of Cheddar, Colby and Monterey Jack cheese.

Easy-Set A986 Frozen 1000 u

Chr.Hansen's A2000 culture system provides culture blends for continuous direct vat set use.

These cultures contain special strains selected for their phage resistance and ability to produce lactic acid quickly.

A2000 cultures produce less galactose than most other Cheddar cultures.

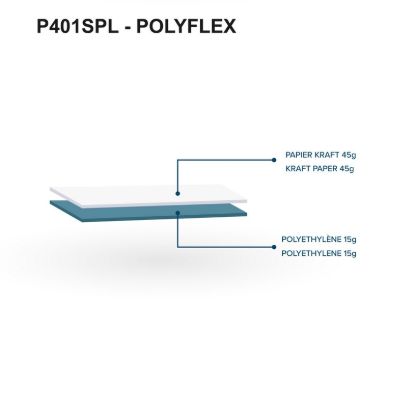

Polyflex - Limited edition

Paper-based structure with a polyethylene inner layer for sealability.

Ideal for cut and wrap application for cheese shops and for whole wheel transport of aged cheeses.

Cutting wires for cheese chopper Pro (set of 6)

The Cheese chopper Pro is the wire cutter for cheese specialists.

This cutter cuts every type of cheese down to size and is especially suited to soft cheeses.

What makes this cutter so exceptional is the special mechanism behind the wire.

It has an improved guidance mechanism, thus reducing the chances of wire breakage and increasing the ease of cutting in one smooth movement.

The ergonomic grip makes the sturdy wire easy to handle, and the wire length is optimized for ease of use.

Boska also devoted extra attention to the replacement of the wire.

If it happens to break, it can be easily replaced by one of the six spare wires included.

Just pop it in – no tools required.

The Cheese chopper Pro is equipped with an anti-slip base, so it won’t drift around on a smooth work surface.

You can choose from two types of feet enclosed in the package:

rubber and suction cups.

The device has a compact shape and the positioning of the feet can be adjusted which allows it to fit on virtually every counter.

The frame is made of super thick plastic, and it has stainless steel wires, making it extremely durable, strong, food-safe, and dishwasher-safe.

In short – it’s super convenient.

Compact wire cutter Suitable for all cheeses New guidance mechanism – less wire breakage and it’s easier to cut Easy wire replacement Includes two types of anti-slip feet Fits on every counter Includes six spare wires Made of super-strong plastic so it’s durable and dishwasher-safe

CHY-MAX® Powder Extra NB 500 g

CHY-MAX® Powder Extra NB is a pure chymosin produced by submerged fermentation on a vegetable substrate with Aspergillus niger var.

awamori kept under contained conditions and not present in the final product.

The product contains a milk-clotting enzyme which is highly specific for kappa-casein, resulting in very good curd formation.

The general proteolitic activity also has a significant influence on the flavor and texture development of cheeses.

The active milk-coagulating enzyme is chymosin (EC 3.4.23.4).

STI-12 Freeze-dried 50 u

Thermophilic lactic acid culture.

The culture is primarily applied in Pasta Filata cheese types e.

g Mozzarella and Pizza cheese types.

The culture can be applied alone or in combination with other lactic acid cultures, e.g. Lactobacillus delbrueckii subsp.bulgaricus and Lactobacillus helveticus.

LH 100 Freeze-dried 50 DCU

Freeze-dried concentrated lactic starter for the direct vat inoculation of milk and mil bases.

Store at temperature at 4 degrés in dry atmosphere.

When stored at negative temperature, keep the sachet at room temperature for 30 to 60 minutes before opening.

If not, the performance of culture is affected.

Prolonged exposure at room temperature will reduce is in powder form.

Add directly to the manufacturing milk as soon as the agitation blades of the vat are covered with milk.

Avoid foam and air introduction in the milk.